In the world of metalworking and CNC precision manufacturing, turning tools play a critical role in shaping, finishing, and refining components that drive industries forward — from aerospace and automotive to energy, defense, and general machinery. As product designs become increasingly complex and material performance requirements rise, the demand for high-performance, reliable, and durable turning tools has never been greater.

HAOCHENG, a leading manufacturer of advanced cutting tools, continues to set benchmarks in precision engineering through innovative design, material science, and manufacturing excellence. The company’s turning tool solutions are developed to meet the rigorous standards of today’s global machining industries.

1. Understanding Turning Tools: The Foundation of Metal Cutting

Turning is a machining process in which a cutting tool removes material from the rotating workpiece, typically performed on a lathe or CNC turning center. The cutting tool must withstand high temperatures, mechanical stress, and friction while maintaining precise geometry.

Turning tools come in multiple forms — including external turning, internal boring, facing, threading, and grooving tools. The choice of tool geometry, insert grade, and coating determines the machining efficiency and surface finish.

At HAOCHENG, each turning tool is designed using advanced CAD/CAM modeling and manufactured from high-grade tungsten carbide, cermet, or coated carbide materials, ensuring long service life and excellent cutting stability.

2. The Core Advantages of HAOCHENG Turning Tools

HAOCHENG’s turning tools combine innovation, performance, and reliability. Every design detail—from insert geometry to edge preparation—is optimized for productivity and precision.

Key Advantages:

High Wear Resistance:

Using advanced PVD and CVD coatings, such as TiAlN and AlTiN, HAOCHENG tools deliver extended tool life even under high-speed cutting conditions.

Excellent Chip Control:

Unique chip breaker geometries enhance chip evacuation and minimize built-up edge, ensuring smoother machining and reduced downtime.

Precision Edge Preparation:

Micro-geometry optimization guarantees superior surface finish and dimensional accuracy.

Material Versatility:

Suitable for a wide range of materials — including steel, stainless steel, cast iron, aluminum, titanium, and superalloys.

High Thermal Stability:

Proprietary coatings and submicron carbide substrates maintain hardness and oxidation resistance under extreme heat.

With these attributes, HAOCHENG turning tools not only reduce production costs but also improve machining consistency, making them the go-to solution for both CNC manufacturers and precision engineering firms.

3. Technical Innovation: From Raw Material to Precision Tool

HAOCHENG integrates modern production technologies and strict quality control at every stage:

Powder Metallurgy & Sintering: Produces dense and uniform carbide substrates with excellent toughness.

CNC Grinding: Guarantees precise rake and clearance angles for consistent cutting performance.

Coating Technology: Utilizes advanced PVD/CVD systems to apply nanostructured coatings with superior adhesion.

Inspection & Testing: 100% dimensional and performance inspection through CMM measurement, microscope edge analysis, and wear simulation.

Each tool passes through ISO 9001:2015-certified production processes, ensuring international quality consistency.

This meticulous approach allows HAOCHENG to provide not just tools, but engineering solutions that maximize machining efficiency and tool economy.

4. Applications Across Industries

Turning tools form the backbone of component manufacturing in nearly every industrial sector.

Automotive Industry: Machining of crankshafts, brake discs, and transmission housings.

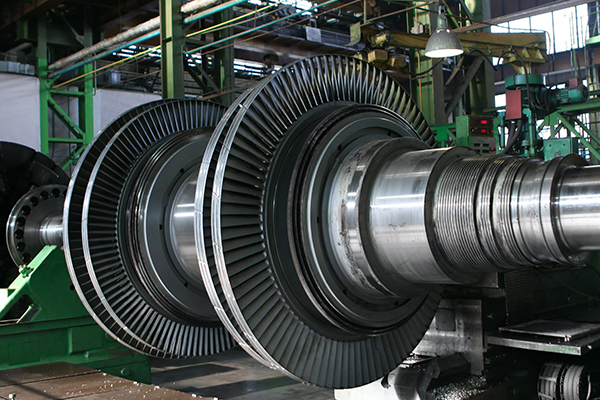

Aerospace: Titanium and Inconel alloy turning for turbine components.

Energy Sector: Precision finishing of valves, pumps, and compressor parts.

General Engineering: Turning of shafts, bearings, and custom mechanical parts.

Medical Equipment: High-precision small-diameter turning for surgical instruments and implants.

By combining precision geometry and application-specific coating, HAOCHENG ensures consistent performance even under heavy-duty or high-speed conditions.

5. Why Choose HAOCHENG Turning Tools

What sets HAOCHENG apart in the cutting tool industry is its commitment to customization and innovation.

The company’s R&D team collaborates directly with customers to design tools tailored to their machining environment — optimizing tool geometry, insert grade, and cutting parameters for maximum productivity.

Additionally, HAOCHENG’s automated production lines, advanced coating facilities, and global distribution network ensure fast delivery and reliable technical support to B2B partners worldwide.

HAOCHENG turning tools help manufacturers achieve:

Higher metal removal rates

Reduced cycle time

Improved part quality

Lower total tooling cost

This performance-driven approach has made HAOCHENG a trusted partner for precision machining solutions globally.

6. Conclusion: Shaping the Future of Precision Machining

As industries advance toward smarter, more efficient manufacturing, the role of high-performance turning tools continues to grow in importance.

Through innovation, material excellence, and precision craftsmanship, HAOCHENG has established itself as a global leader in turning technology — enabling manufacturers to achieve higher accuracy, greater efficiency, and unmatched reliability.

When you choose HAOCHENG, you invest not just in a tool — but in a complete solution engineered for success.