In today’s fast-paced manufacturing and packaging industry, efficiency, accuracy, and reliability are key to maintaining a competitive edge. One of the most critical components in any production line is the capping system — the mechanism that ensures bottles, jars, and containers are securely sealed. Among the various options available, the semi automatic capping machine has emerged as a preferred solution for businesses seeking the perfect balance between automation and flexibility.

At Bluemann, we specialize in designing and manufacturing high-quality semi automatic capping machines that combine precision, durability, and ease of use. Our machines are trusted by manufacturers worldwide for their reliability, adaptability, and performance, making them an essential investment for packaging lines of all sizes.

1. What Is a Semi Automatic Capping Machine

A semi automatic capping machine is a versatile device designed to place and tighten caps on bottles or containers with a combination of manual and automated processes. Unlike fully automatic capping machines, semi automatic models require minimal operator input, allowing for cost-effective and flexible operation while maintaining high accuracy.

These machines are ideal for small to medium production runs, pilot projects, or businesses that need a versatile capping solution without investing in fully automated systems. They handle a wide variety of cap types, including screw caps, snap-on caps, and crown caps, ensuring consistent sealing across multiple container sizes.

2. Key Features of Bluemann Semi Automatic Capping Machines

Bluemann semi automatic capping machines are engineered for performance, reliability, and user convenience. Some standout features include:

Adjustable Torque Control: Ensures consistent sealing without damaging containers or caps.

Ergonomic Design: Reduces operator fatigue during prolonged production runs.

Versatility: Compatible with bottles and jars of various shapes, sizes, and materials.

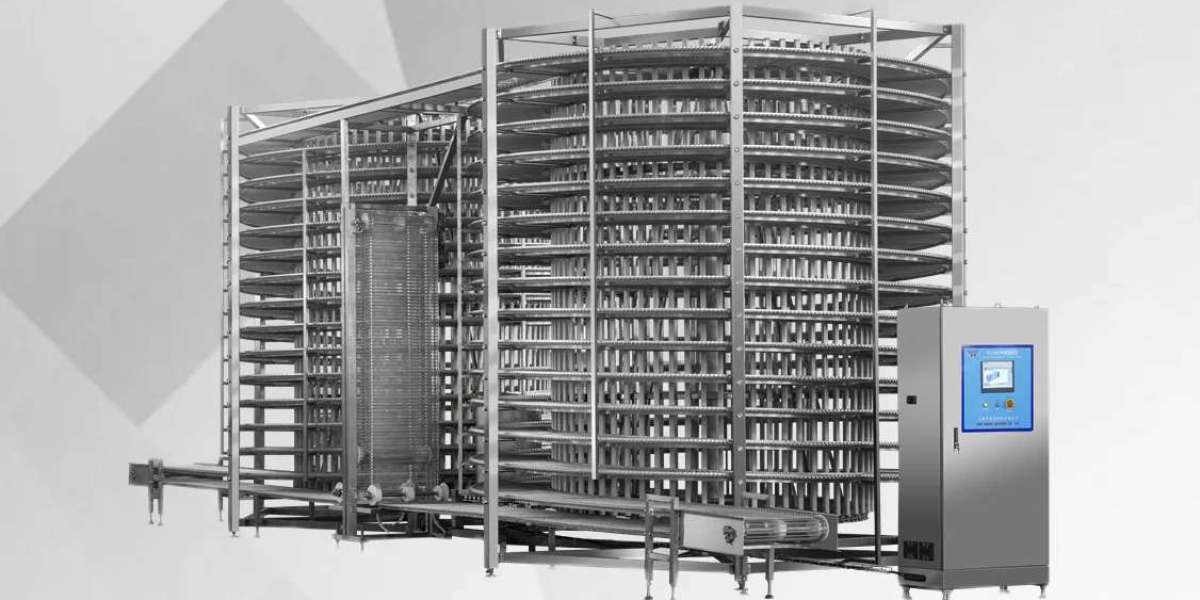

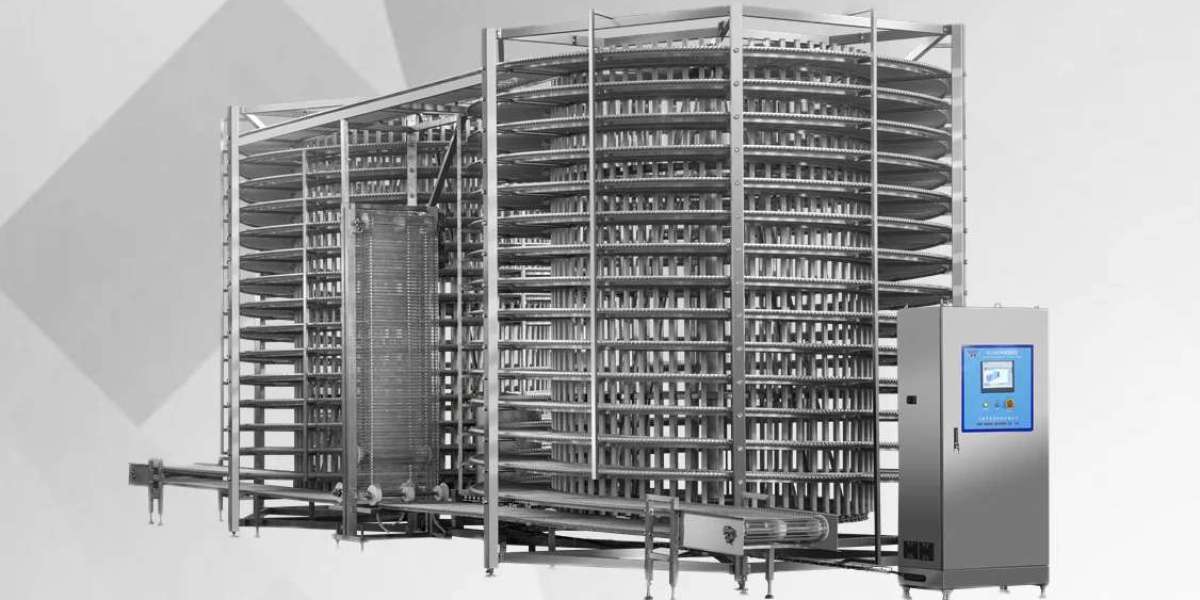

Durable Construction: Made from stainless steel and high-quality components to withstand continuous use.

Easy Maintenance: Minimal parts and accessible design for quick cleaning and servicing.

These features make Bluemann’s machines suitable for industries ranging from beverages and pharmaceuticals to cosmetics and chemicals.

3. Benefits of Using a Semi Automatic Capping Machine

Investing in a semi automatic capping machine offers several advantages over manual or fully automated alternatives:

a. Enhanced Efficiency

Manual capping is time-consuming and prone to human error. Semi automatic machines streamline the process, allowing operators to cap more containers in less time while maintaining uniform quality.

b. Cost-Effectiveness

Compared to fully automatic systems, semi automatic machines are more affordable and require lower operational costs, making them ideal for small and medium-scale production.

c. Consistent Quality

Bluemann’s machines provide precise torque control and cap alignment, preventing leaks, spillage, and product wastage. This consistency enhances brand reputation and reduces customer complaints.

d. Flexibility

Semi automatic machines can easily accommodate different container sizes and cap types. This versatility is particularly valuable for companies with varied product lines or frequent design changes.

4. Why Manufacturers Choose Bluemann

At Bluemann, quality, innovation, and customer satisfaction are our top priorities. Our semi automatic capping machines are built to meet international standards, combining precision engineering with durable materials.

Manufacturers choose Bluemann because our machines offer:

Reliability: Engineered for consistent performance under continuous operation.

User-Friendly Operation: Minimal training required to operate efficiently.

Long Lifespan: High-quality components ensure years of maintenance-free service.

Adaptability: Easily configurable for multiple products and production lines.

These qualities make Bluemann a trusted partner for businesses looking to enhance their packaging operations.

5. Future of Semi Automatic Capping Machines

As the packaging industry evolves, semi automatic capping machines are becoming more sophisticated. Innovations include digital torque settings, quick-change systems for different cap sizes, and integration with other semi automated packaging lines.

Bluemann continuously invests in research and development to improve machine efficiency, durability, and adaptability. Our goal is to provide clients with machines that not only meet current demands but also adapt to future production needs.

Conclusion

A semi automatic capping machine is a vital investment for any manufacturer seeking to improve packaging efficiency, maintain consistent product quality, and reduce operational costs. With their combination of flexibility, precision, and reliability, these machines strike the perfect balance between manual effort and automation.

Bluemann semi automatic capping machines deliver superior performance across industries, ensuring products are securely sealed, production lines run smoothly, and businesses remain competitive. Investing in a Bluemann machine means investing in quality, efficiency, and peace of mind for your packaging operations.