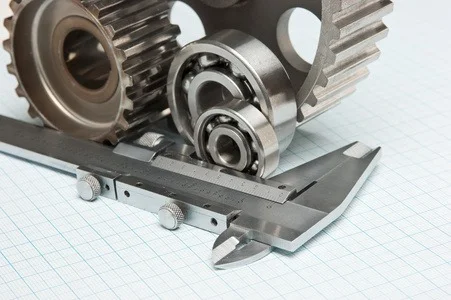

In today’s precision-driven manufacturing environment, accurate measurements are the backbone of quality control and product reliability. Among the essential tools for achieving high-precision measurement, the caliper with depth gauge rod stands out for its versatility. Unlike standard calipers, this instrument allows operators not only to measure external and internal dimensions but also to assess depths with exceptional accuracy, making it indispensable for packaging, mechanical, and industrial production lines.

West Lake Packaging Machinery, a leading provider of advanced packaging solutions, leverages these calipers to ensure dimensional compliance across its machinery components, guaranteeing consistent output quality.

Understanding the Caliper with Depth Gauge Rod

A caliper with depth gauge rod combines traditional caliper jaws with a precision depth measuring rod that extends beyond the base of the caliper. This design enables users to:

Measure internal diameters of cylindrical components

Accurately determine depth in recesses, slots, or cavities

Maintain consistency in repetitive measurements

The depth gauge rod typically provides a measurement range corresponding to the caliper’s scale, ensuring that the operator can measure both shallow and deep cavities without sacrificing accuracy.

Key Features and Technical Advantages

High Accuracy and Resolution

Quality calipers with depth gauge rods offer resolutions up to 0.01 mm or 0.0005 inches, allowing precise assessment of critical tolerances in packaging machinery components such as conveyor slots, filler heads, and sealing jaws.

Multi-Functional Measurement Capabilities

By integrating external, internal, step, and depth measurements into one instrument, the caliper with depth gauge rod reduces the need for multiple tools, streamlining inspection processes and saving both time and operational cost.

Digital vs. Vernier Options

Modern calipers include digital readouts that provide instant measurements with minimal error, while vernier calipers remain a reliable choice for operators accustomed to analog systems. Both versions include a depth rod extension, ensuring comprehensive dimensional verification.

Material and Build Quality Considerations

The accuracy and durability of a caliper with depth gauge rod depend on the material and construction:

Stainless Steel Construction: Ensures corrosion resistance and long-term dimensional stability, critical in humid or dusty packaging environments.

Hardened Measuring Surfaces: Reduces wear and maintains measurement precision over time.

Smooth Rod Movement: Precision-machined depth rods minimize friction, ensuring repeatable and reliable readings.

West Lake Packaging Machinery prioritizes calipers built from high-quality materials to maintain accuracy in high-throughput packaging systems.

Applications in Packaging Machinery

Internal and External Component Measurement

Operators use the caliper to verify the external dimensions of machine frames, internal diameters of guide rails, and slot widths of conveyor systems, ensuring all parts meet strict tolerance standards.

Depth Measurement in Product Lines

Depth gauge rods are particularly useful in checking fill-level channels, die cavities, and sealing plate recesses, where precise depth measurement is critical for consistent product quality.

Quality Assurance in Multi-Stage Production

By integrating calipers with depth gauge rods into routine QA checks, packaging machinery operators can detect component deviations early, preventing misalignment, leaks, or defective packaging output.

Best Practices for Calibration and Usage

Routine Calibration

Calipers must be calibrated periodically against gauge blocks or reference standards to maintain measurement accuracy, particularly when used in industrial environments with vibration, dust, or temperature fluctuations.

Proper Handling and Storage

Avoid dropping or applying excessive force to the depth rod

Clean measuring surfaces before use to prevent debris from affecting readings

Store in protective cases to avoid mechanical deformation

Training and Operator Proficiency

Proper training ensures that personnel correctly measure depths without tilting the rod or misaligning the caliper jaws, which could introduce significant measurement errors.

Integration with West Lake Packaging Machinery Systems

West Lake Packaging Machinery employs calipers with depth gauge rods in both pre-assembly inspection and post-assembly quality checks, integrating measurement data into digital QA logs. This approach ensures:

Continuous compliance with design tolerances

Reduced scrap and rework costs

Higher consistency and reliability of packaging machinery operations

The depth measurement capability specifically allows engineers to optimize machinery setups, ensuring uniformity across production batches.

Conclusion: Precision, Efficiency, and Reliability

The caliper with depth gauge rod is more than a basic measuring tool—it is a cornerstone for precision, efficiency, and quality assurance in modern industrial and packaging systems. West Lake Packaging Machinery’s adoption of high-precision calipers ensures dimensional accuracy, reduces defects, and supports the delivery of high-quality packaged products worldwide.

By combining robust build quality, versatile measurement capabilities, and proper calibration practices, manufacturers can maximize the effectiveness of this indispensable tool.