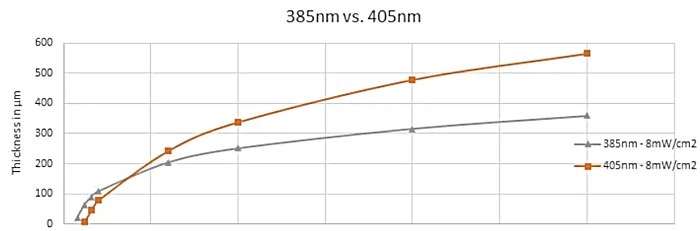

Currently on the market light-cured 3D printing to face forming technology, its light source is generally DLP projection or LCD black and white screen, UV light wavelength is generally 385nm or 405nm. what are the advantages and disadvantages of these two wavelengths, the following look at the actual experimental research.

Experimental conditions:

Optical energy density: 8mW/cm2

Wavelength: 405nm and 385nm

Test the relationship between curing time and curing thickness at different wavelengths, and plot the curing curve.

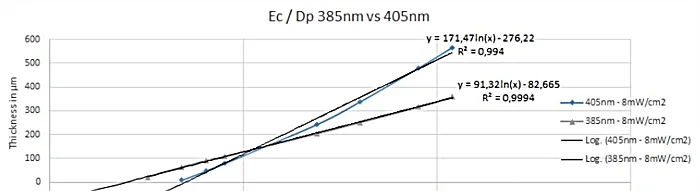

Experimental Conclusion:

385nm starts curing more efficiently (lower Ec)

405nm cures thicker layers more efficiently (higher Dp)

The steeper slope of the 405nm test makes it more likely that a complete cure will occur, but it also improves print speed for thicker layers.

As you can see from the graph, the Ec and Dp values are different for 385nm and 405nm.

Difference between 385nm and 405nm

In light-curing 3D printing, the difference between 385nm and 405nm wavelengths is mainly reflected in the following aspects:

1. Light source and energy

385nm: UV LEDs or lasers are usually used, with higher energy.

405nm: mostly use UV LED, energy is relatively low.

2. Resin curing effect

385nm: high energy, fast curing speed, suitable for high-precision printing.

405nm: curing speed is slightly slower, but the curing layer is more uniform.

3. Printing accuracy

385nm: shallow penetration depth, suitable for high-precision models.

405nm: large penetration depth, slightly lower precision, better interlayer bonding.

4. Equipment cost

385nm: higher cost of light source, more expensive equipment.

405nm: lower cost of light source, more affordable equipment.

5. Application Scene

385nm: suitable for high-precision requirements of the field, more friendly to the transparent material.

405nm: suitable for general prototyping and education and other scenes.

6. Printer

385nm: Suitable for DLP.

405nm: suitable for LCD, relatively friendly to LCD screen.

7. Safety

385nm: Stronger UV rays, need more protection.

405nm: relatively safe, less protection required.

https://www.y-crystaled.net/wavelengths-for-light-cured-3d-printing.html