In the modern industrial and architectural fields, Aerospace Interior Trim Profiles, with their unique advantages, are becoming indispensable important materials in various engineering designs and manufacturing. This article will comprehensively explore the application, advantages, manufacturing processes and future development trends of Aerospace Interior Trim Profiles, helping readers gain an in-depth understanding of the current situation and prospects of this industry.

I. Definition and Characteristics of Aerospace Interior Trim Profiles

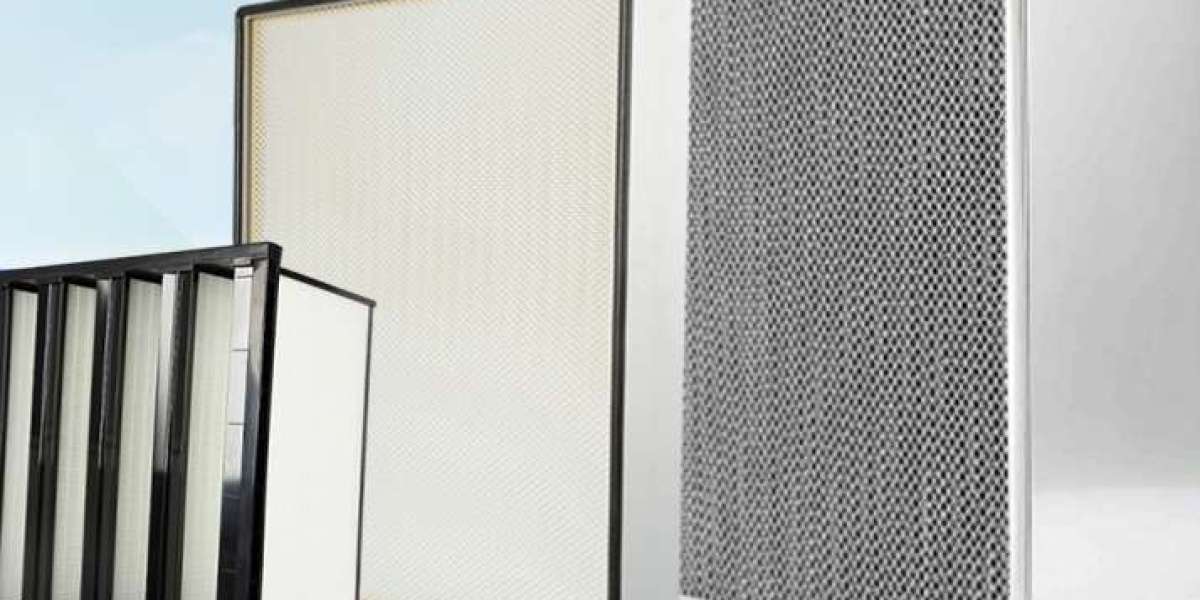

Aerospace Interior Trim Profiles refer to track structures processed and formed using aluminum alloy materials, and are often used in fields such as mechanical equipment, transportation systems, and buildings. Compared with traditional steel, Aerospace Interior Trim Profiles have a lighter weight, stronger corrosion resistance and better processing performance.

1.1 Lightweight advantage

The density of aluminium alloy is approximately one-third that of steel, which makes Aerospace Interior Trim Profiles particularly suitable for application scenarios where structural weight reduction is required. In industries such as shipping and aviation, lightweight design has become a trend, and Aerospace Interior Trim Profiles precisely meets this demand.

1.2 Corrosion Resistance

The naturally formed oxide film on the surface of aluminum alloy endows it with excellent corrosion resistance. Especially in humid, high-salinity or chemically corrosive environments, Aerospace Interior Trim Profiles can maintain a longer service life. This is particularly important for transportation and outdoor equipment.

1.3 Excellent processing performance

Aerospace Interior Trim Profiles have good plasticity and can be formed in the early stage through processes such as extrusion and forging to meet the design requirements of different users. Meanwhile, the welding, processing and surface treatment technologies of aluminum alloys have become increasingly mature, providing a foundation for their diversified applications.

Ii. Application Fields of Aerospace Interior Trim Profiles

Aerospace Interior Trim Profiles have been widely applied in multiple fields, including but not limited to mechanical manufacturing, architectural decoration, transportation, etc.

2.1 Mechanical Manufacturing

In modern mechanical manufacturing, Aerospace Interior Trim Profiles are often used in the brackets, guide rails or frames of various transmission equipment. The lightweight design of these components not only enhances the energy efficiency of the equipment but also reduces transportation and installation costs.

2.2 Architectural Decoration

In the construction industry, Aerospace Interior Trim Profiles are applied in structures such as window frames, door frames and curtain walls. Its beautiful appearance, rich color options and weather resistance make Aerospace Interior Trim Profiles an important part of modern architectural design.

2.3 Transportation

In the transportation industry, Aerospace Interior Trim Profiles have long been used to manufacture components of various vehicles, such as guide rails and vehicle body structures for rail transit. Due to the lightweight nature of aluminium alloy, it can enhance transportation efficiency and reduce energy consumption.

2.4 Electronics and Electrical Engineering

In electronic and electrical equipment, the application of Aerospace Interior Trim Profiles is increasing. They are widely used in the enclosures and brackets of various electrical equipment. Due to their excellent heat dissipation performance and electromagnetic interference protection capability, they enhance the stability and safety of the equipment.

Iii. Manufacturing Process of Aerospace Interior Trim Profiles

The manufacturing process of Aerospace Interior Trim Profiles involves multiple links, from the selection of raw materials to the processing of finished products. Each step has a profound impact on the quality of the final product.

3.1 Material Selection

There are many types of aluminum alloys, and the commonly used ones include series such as 6061, 6063, and 7075. The composition and properties of these alloys determine the fields and occasions in which they are applicable. When manufacturing track profiles, the appropriate aluminum alloy should be selected based on specific application scenarios.

3.2 Extrusion Molding

Extrusion molding is the main production process of Aerospace Interior Trim Profiles. By heating the aluminium ingot to a certain temperature and then extruding it into profiles of specific shapes with strong pressure. After extrusion, the profiles need to be cooled and cut to form the finished products of the required length.

3.3 Surface Treatment

In order to improve the corrosion resistance and aesthetics of Aerospace Interior Trim Profiles, the surface treatment process is of crucial importance. Common surface treatment methods include anodizing, electrophoretic painting, sandblasting, etc. Different processing techniques can endow Aerospace Interior Trim Profiles with different appearances and functions.

3.4 Welding and Assembly

In cases where multiple aluminum alloy components need to be assembled into one unit, the welding process becomes particularly important. The welding of aluminum alloy is relatively complex and requires the selection of appropriate welding methods, such as argon arc welding, based on specific materials, to ensure the strength and reliability of the welded joint.

Iv. Market Prospect of Aerospace Interior Trim Profiles

With the deepening of the global concept of green environmental protection, aluminum alloy, as a material with strong recyclability, will enjoy a broad market space in the future. According to market research, the demand for Aerospace Interior Trim Profiles is expected to continue to grow in the coming years.

4.1 The Importance of Sustainable Development

The recyclability of aluminium alloy makes it a sustainable material. Once a product reaches the end of its life cycle, it can be recycled and reused to reduce the environmental burden. Therefore, an increasing number of enterprises give priority to aluminum alloy materials in their designs to align with the trend of environmental protection.

4.2 Technological Innovation and Upgrading

With the continuous development of new technologies, Aerospace Interior Trim Profiles will also keep innovating in forming processes and surface treatment technologies. The development of high-performance aluminum alloy and the expansion of automated production lines will all promote the progress and development of the industry.

4.3 Expansion of the global market

In the international market, the demand for Aerospace Interior Trim Profiles is also on the rise, especially in the Asian region. With the acceleration of the industrialization process, the market potential is huge. Technological exchanges and cooperation among countries will further promote the development of the aluminum alloy industry.

V. Conclusion

Aerospace Interior Trim Profiles have shown broad application prospects in modern industry with their lightweight, corrosion resistance and excellent processing performance. With the continuous advancement of technology and the continuous improvement of market demand, Aerospace Interior Trim Profiles will undoubtedly play a more important role in future engineering design and manufacturing. If enterprises can seize this trend, they will surely win more development opportunities and economic benefits.

Aerospace Interior Trim Profiles https://www.rongxinhao.com/Aerospace-interior-trim-profile.html