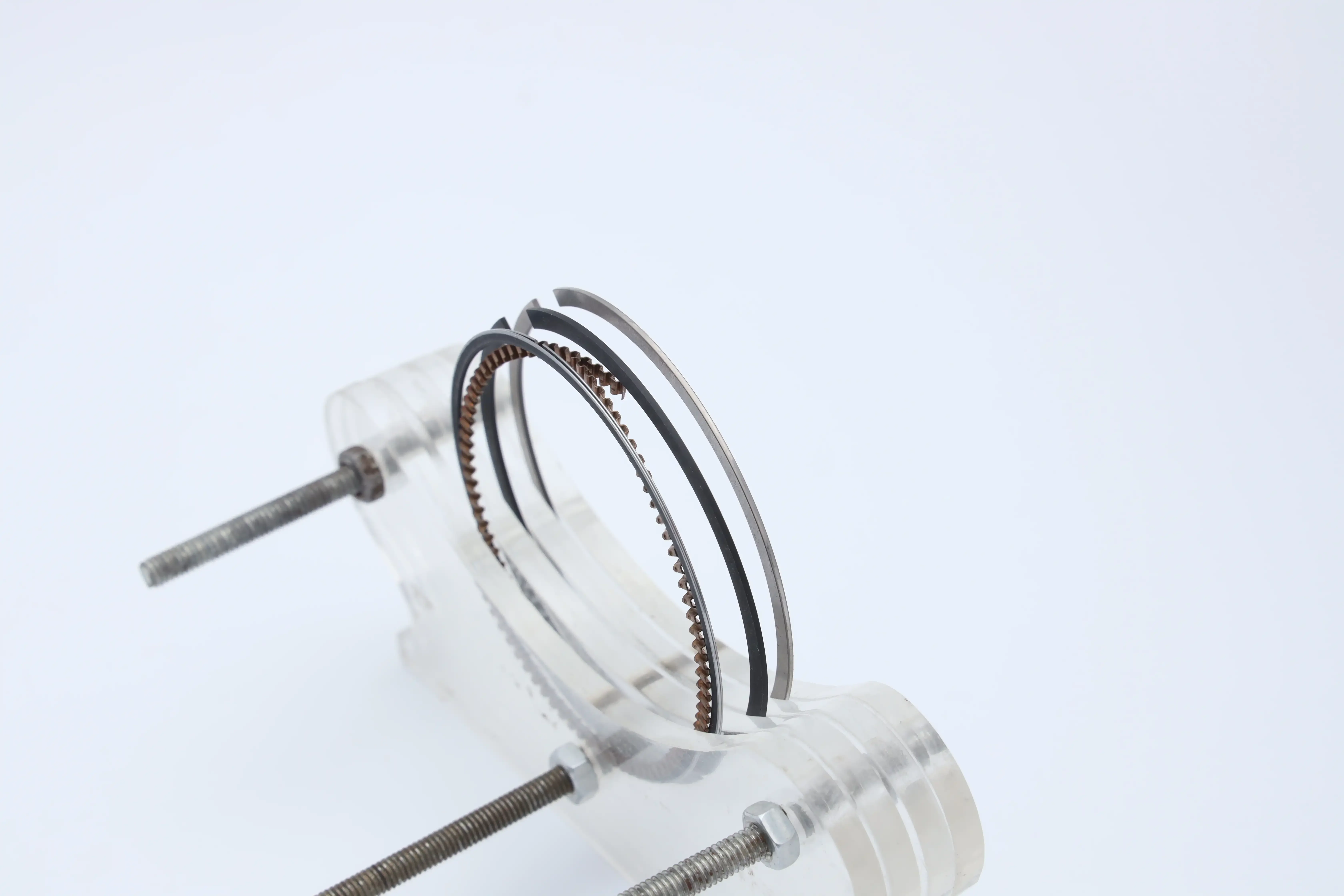

Piston rings play a crucial role in the performance and efficiency of an engine. They are essential components that help seal the combustion chamber, control oil consumption, and facilitate heat transfer from the piston to the cylinder wall. JYPR's automotive piston rings are designed specifically for Toyota models to ensure a perfect fit and superior performance. Made of high-quality materials, these piston rings not only improve the sealing of the engine, but also effectively reduce fuel consumption and emissions. Whether it is daily driving or high-performance needs, JYPR's piston rings can provide reliable support to help Toyota owners improve the overall performance and durability of their vehicles. Choosing JYPR, you will experience a smoother driving experience and longer engine life.

Types of Piston Rings

1. Compression Rings

Compression rings are designed to seal the combustion chamber and prevent the escape of gases during the combustion process. They are typically made from cast iron or steel and come in various designs, including:

Conventional Compression Rings: These are the most common type, featuring a simple rectangular cross-section. They provide effective sealing but may wear out faster under high-performance conditions.

Tapered Compression Rings: These rings have a tapered profile that allows for better sealing and reduced friction. They are often used in high-performance engines where efficiency is paramount.

2. Oil Control Rings

Oil control rings are responsible for regulating the amount of oil that reaches the combustion chamber. They help minimize oil consumption and prevent excessive smoke from the exhaust. There are two main types:

Three-Piece Oil Control Rings: This design consists of two thin rings and a spacer. The two rings work together to scrape excess oil off the cylinder wall, while the spacer maintains the correct spacing.

Single-Piece Oil Control Rings: These rings are simpler and often used in lower-performance engines. They are easier to install but may not provide the same level of oil control as the three-piece design.

3. Specialty Rings

In addition to standard compression and oil control rings, Toyota also utilizes specialty rings for specific applications:

Low-Friction Rings: These rings are designed to reduce friction between the piston and cylinder wall, improving fuel efficiency and performance. They are often coated with materials like molybdenum or graphite.

Thermal Barrier Rings: These rings are engineered to withstand extreme temperatures and are often used in turbocharged or high-performance engines. They help maintain the integrity of the seal under high heat conditions.

Adaptation Techniques for Piston Ring Fit

1. Ring Gap Adjustment

One of the most critical aspects of piston ring installation is ensuring the correct ring gap. The ring gap is the space between the ends of the ring when it is installed in the cylinder. If the gap is too small, it can lead to ring breakage or excessive pressure buildup. Conversely, if the gap is too large, it can result in poor sealing and increased oil consumption.

To achieve the correct ring gap, technicians often use a feeler gauge to measure the gap and file the ends of the rings as necessary. Toyota recommends specific gap measurements based on engine type and application, ensuring optimal performance.

2. Proper Installation Techniques

The installation of piston rings requires precision and care. Technicians must ensure that the rings are oriented correctly, as each type of ring has a specific installation position. For example, compression rings usually have a marking indicating the top side, while oil control rings may have a specific orientation for optimal oil scraping.

Using a ring compressor during installation can help prevent ring distortion and ensure a snug fit within the cylinder. This tool compresses the rings, allowing for easier insertion into the cylinder bore.

3. Surface Treatment and Coatings

To enhance the performance and longevity of piston rings, many manufacturers, including Toyota, employ various surface treatments and coatings. These treatments can reduce friction, improve wear resistance, and enhance sealing capabilities. Common coatings include:

Chrome Plating: This provides a hard, wear-resistant surface that can extend the life of the rings.

Nitriding: A heat treatment process that hardens the surface of the rings, improving their durability and resistance to wear.

4. Material Selection

The choice of materials for piston rings is crucial for their performance. Toyota often uses advanced materials that can withstand high temperatures and pressures while maintaining flexibility and strength. The selection of materials is based on the specific engine application, with considerations for factors such as:

Engine Type: Different engines may require different ring materials based on their operating conditions.

Performance Requirements: High-performance engines may benefit from specialized materials that offer enhanced durability and reduced friction.

Conclusion

Understanding the types of piston rings and the adaptation techniques for their fit is essential for maintaining the performance and efficiency of Toyota vehicles. By employing the right materials, installation techniques, and surface treatments, Toyota ensures that its engines operate at peak performance, providing drivers with reliability and efficiency. Whether for everyday driving or high-performance applications, the importance of proper piston ring fit cannot be overstated.

https://www.jy-pr.com/types-and-adaptation-techniques-of-cars-piston-ring-fit-toyota.html